tagsurveyor

Lost or misplaced inventory can cost millions of dollars in expedites, re-orders, and write-offs, as well as wasted hours searching for inventory. Physical counts require hours of manual work and are often done very infrequently. Tagging assets with RFID immediately improves inventory tracking, increases accuracy, and saves time. With a TagSurveyor solution, you can increase inventory counts and checks from once-a-month to multiple times per day, even in the largest warehouses. Warehouse and manufacturing facilities, including those operated by the U.S. Government, deploy TagSurveyor to help keep track of assets.

Key Benefits

-

Continuous cycle counting & inventory tracking

-

Powerful data visualization to locate misplaced inventory

-

Reporting tools to highlight discrepant inventory counts

-

Verify inbound & outbound activity at docks

-

24/7 automated data gathering with autonomous charging

Product Features

-

Three RFID antennas for full single pass coverage

-

Precise path and positioning for consistent and maximum tag discovery

-

82 degrees of sensor coverage* to reach tagged items even on tall shelving

-

Up to 7.6m (25ft) of read range*

*Read range, coverage and sensitivity will vary based on environment, tag placement, and tag density.

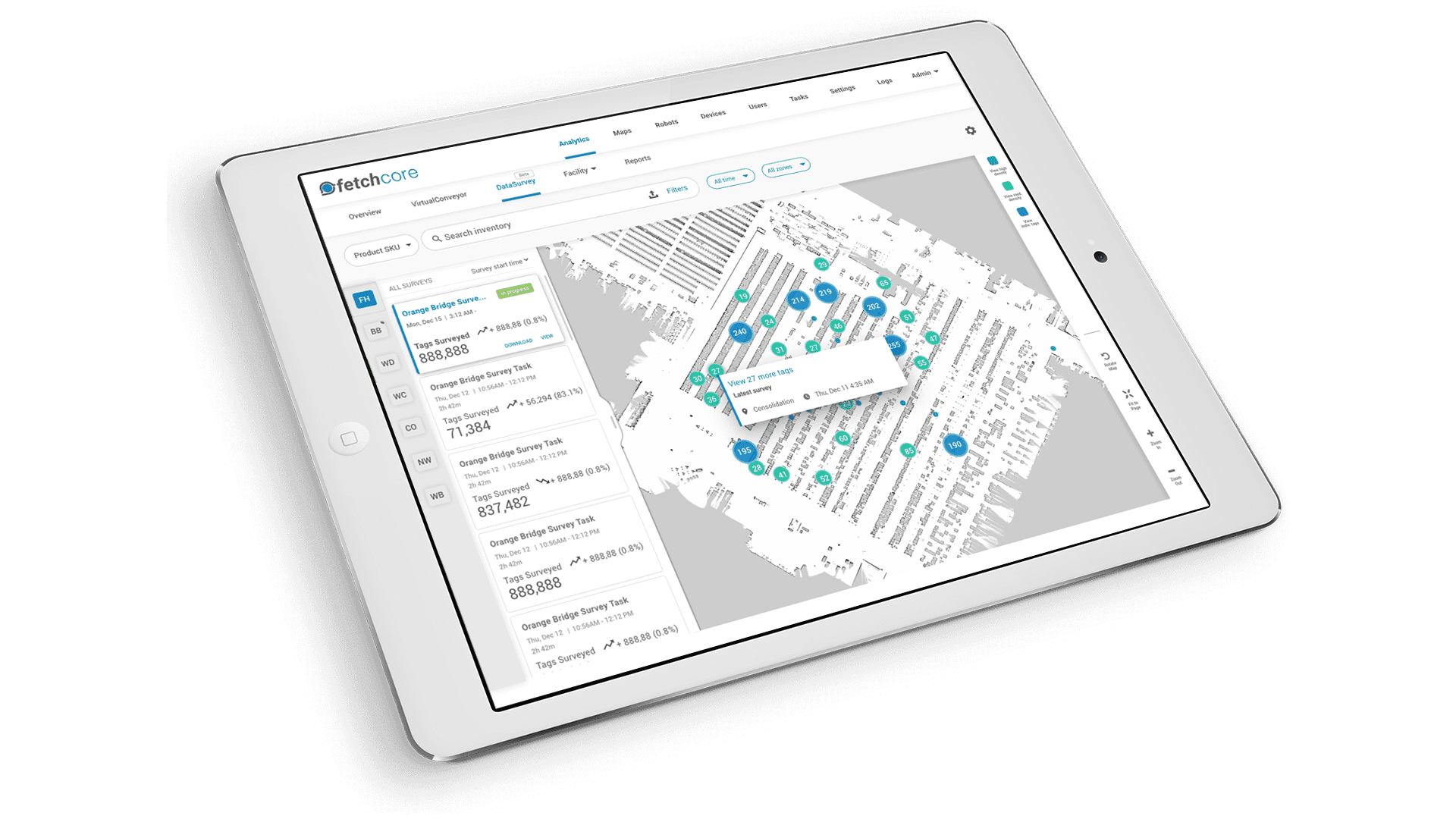

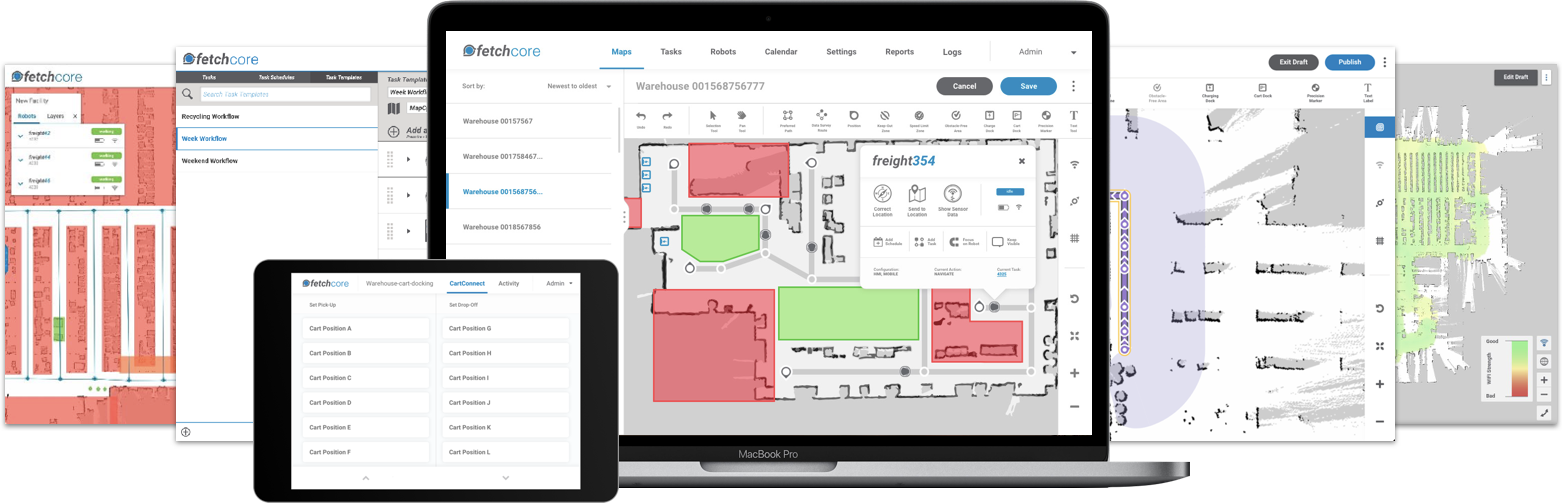

Powerful RFID Visualization with FetchCore Enterprise Software

Better Data

The DataSurvey TagSurveyor RFID solution moves steadily and precisely through your warehouse to provide consistent and reliable results. This eliminates human error and missing data from poorly placed, fixed readers or handhelds.

Faster Data

TagSurveyor operates autonomously and multiple TagSurveyor AMRs can be setup to run 24 hours a day, 7 days a week. Discover inventory shortfalls faster and locate misplaced items. Conduct full physical inventory across millions of square feet multiple times a day instead of manual cycle counting at quarterly intervals.

Cheaper Data

Free people from cycle counting to do higher-value work. TagSurveyor is a dedicated three-shift-per-day, cycle count and inventory location resource. Busy warehouse staff no longer need to spend time on urgent hunts for lost material. TagSurveyor shows you where all your tagged assets are based on your warehouse map.

Deploy in Hours

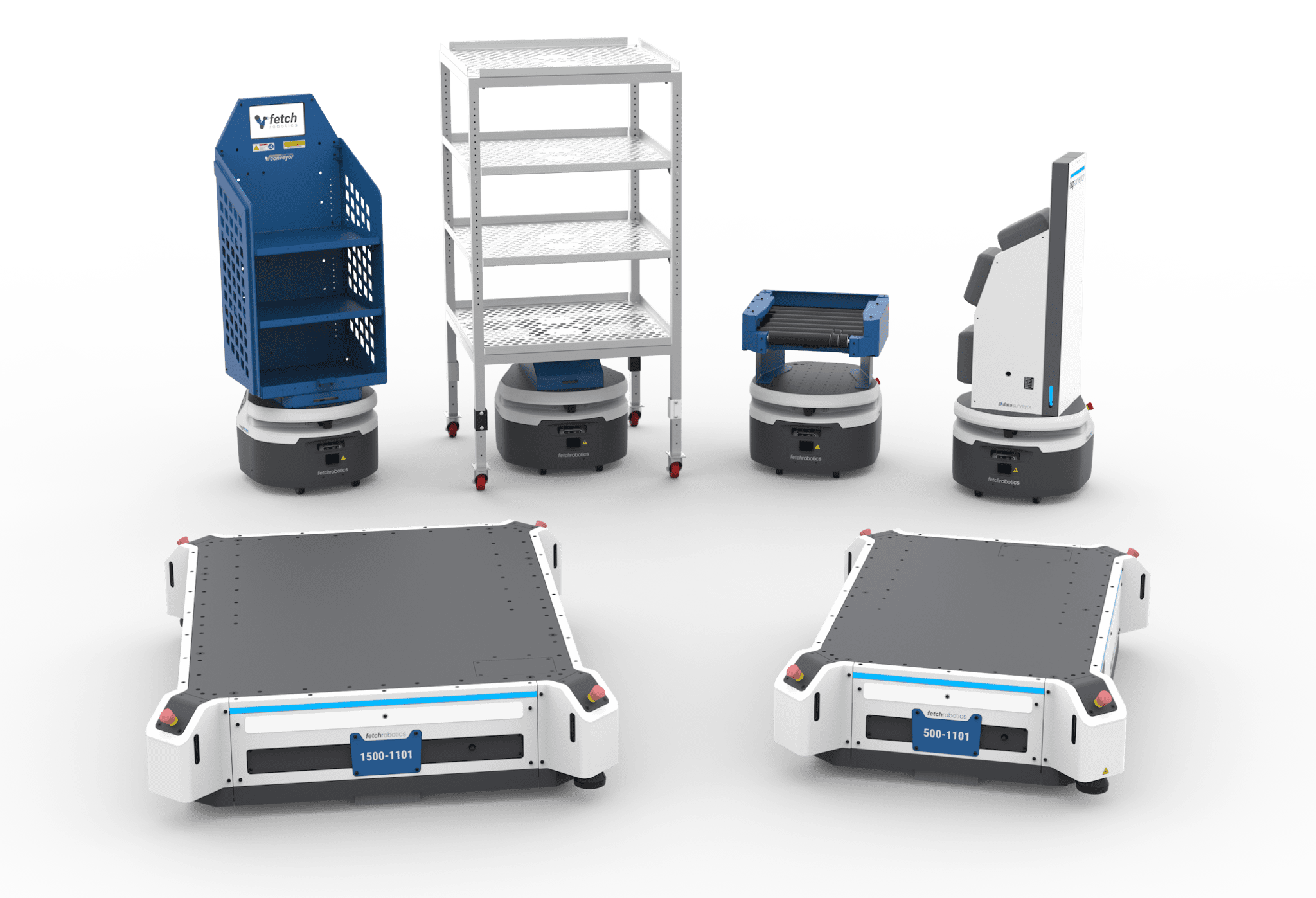

Our FetchCore suite of software and services comes with our Enterprise Robot Planning (ERoP) module. This application simplifies deployment, operation, and optimization of our entire portfolio of Autonomous Mobile Robots (AMRs) for material handling and data collection.

Manage and monitor TagSurveyor robots, as well as your entire Fetch Robotics AMR fleet across multiple warehouse and manufacturing environments. Robots can begin work within just hours – not days, weeks, or months.

Leading 3PLs, manufacturers, and retailers rely on the Fetch Cloud Robotics Platform

Want to learn more about how on-demand automation can improve productivity in your facility? Get started today by contacting the automation experts at Fetch Robotics. With the broadest range of AMRs in the industry, Fetch can help you find, track, and move anything from parts to pallets.